Project Details

Summary

The Formula SAE competition entails not only the conceptualization and design of a 1/3rd scale F1 car, but also the logistics required for sourcing/machining the parts we design. Some of the more complex parts are the suspension uprights which allow us to transfer force from the wheel hub to the suspension system of the car. This year, I was responsible for manufacturing both the front and rear uprights.

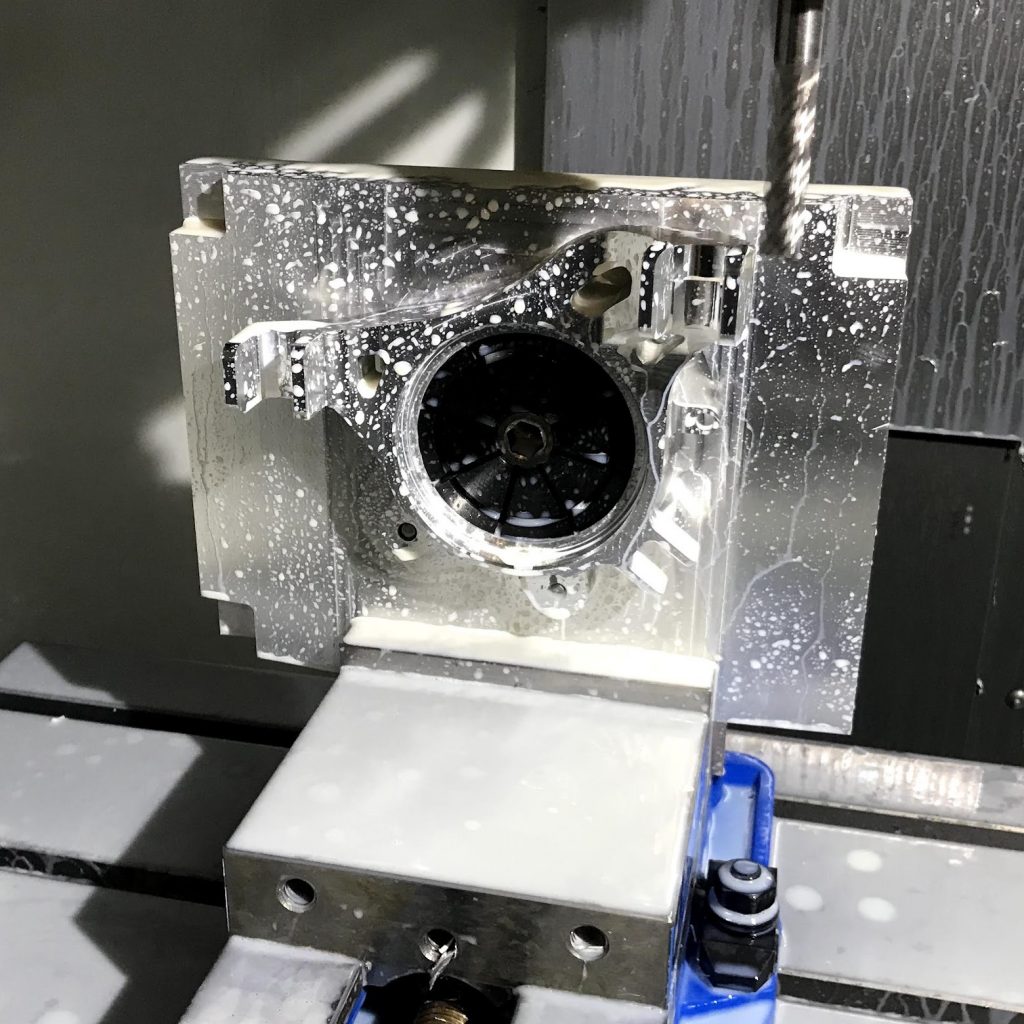

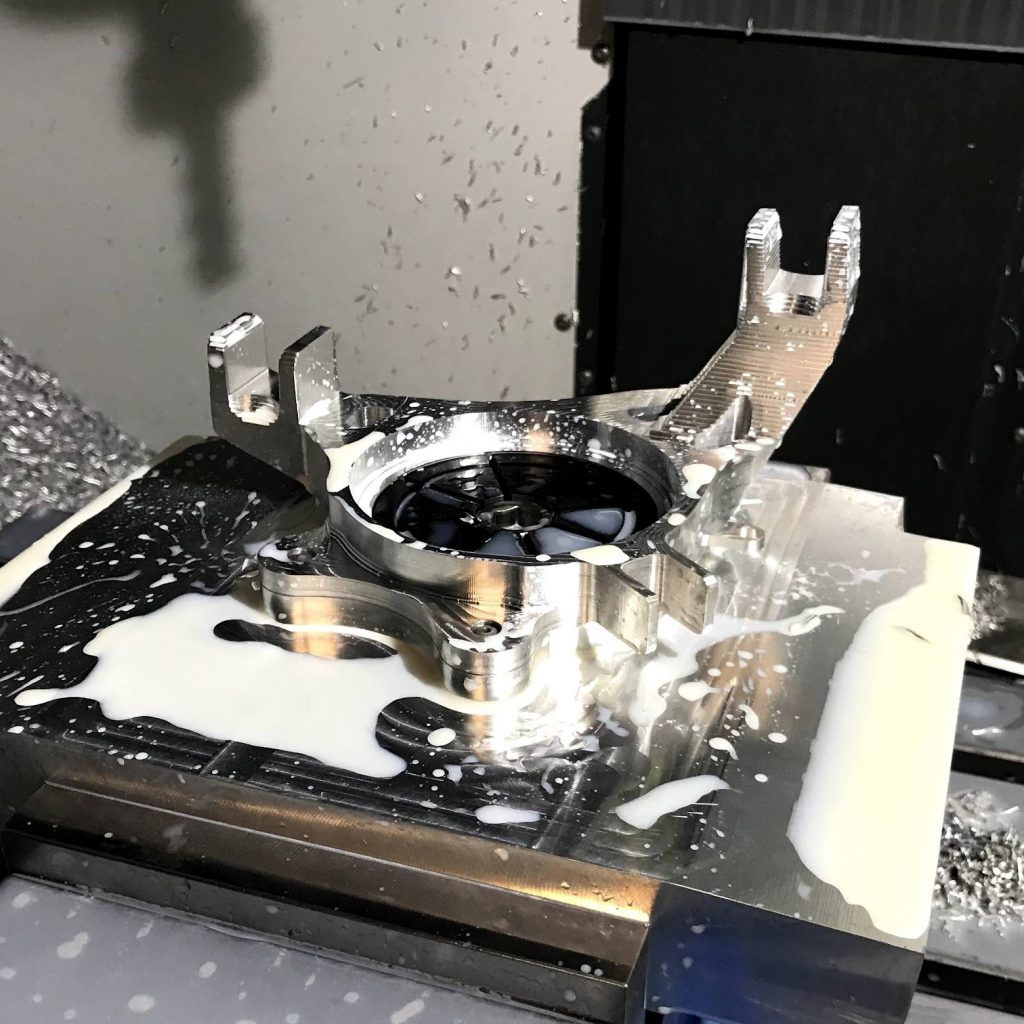

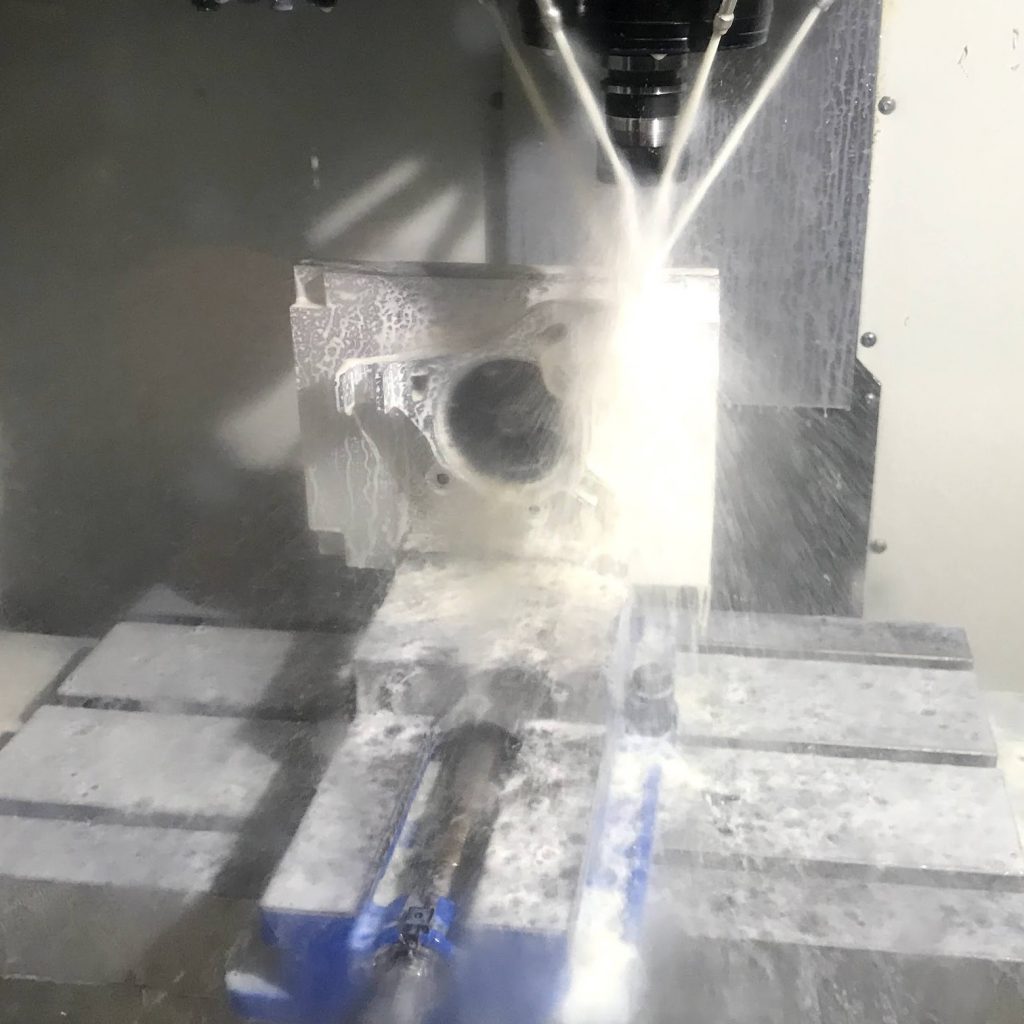

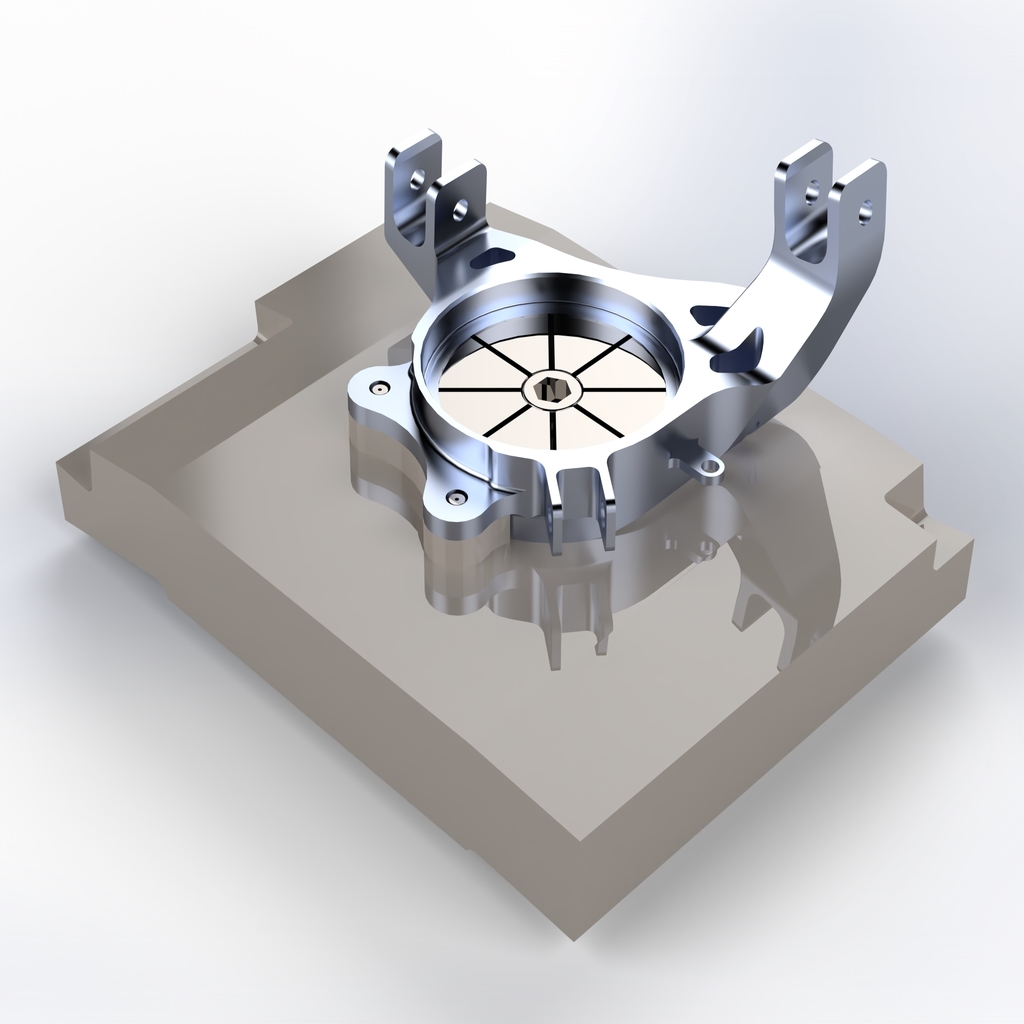

Since the design of the uprights is driven by 3D suspension geometry, there are a couple of elements on the uprights at strange angles. As we only have access to a 3-axis CNC machine, I designed a fixture plate to allow for precise machining of the required features.

The fixture plate is machined out of a billet aluminum and has non-planar angles machined on the left and right sides. The part is secured using an ID-Expansion Clamp from Mitee Bite and located using two diamond pins.

The two bearing bores on each part were successfully machined to a diametral tolerance of ±0.0004″ and ±0.0002″ for the rear and front uprights respectively.